Gathering data and evaluating requirements

This is intended to be a non-technical write up of the selection and installation of a battery inverter energy storage system to be used with local small scale renewable energy generation. It is however necessary to have a basic understanding of what electricity is and how it is measured. The difference between power and energy causes regular confusion so there follows a brief refresher, skip this if you are comfortable with concepts.Measurement of Electricity

For a simple guide to electricity see ' Electricty made simple'(opens in a new tab).Power & Energy

power is the rate at which energy is transferred, measured in Watts andenergy is a measure of the amount of work done, usually measured in Joules … but not by us.

If a heater is rated at 1000 Watts then every second we have converted

electricity into 1000 Joules into heat, in 5 seconds we have done 5000

Joules work (made heat) and in an hour (3600 seconds) we have produced

3600000 Joules of heat. That is a lot of zeros so in order to keep the

numbers easier to use we define an energy 'unit' as 1000W for one hour

known as a kilowatt-hour or kWh.

The kWh energy unit may be familiar because we are charged in kWh on our our energy bills. To get a 'feel' for what one kWh of energy will provide, here are some approximations:

- It will bring about 10 litres of water to boiling point; water has an unusually high 'specific heat capacity' so it takes a lot of energy to increase its temperature.

- Operate a medium sized LCD TV for around 20 hours

- One dishwasher cycle (A rated machine)

Quantifying Batteries

To to add another slight confusion we will also be looking at batteries, which store potential energy in chemical form which can be released to form electricity. Battery capacity is measured in amp-hours (Ah) which is the amount of current, measured in amps, that can be delivered for an hour after which the battery is 'flat'. The reason this measure is useful will become clearer later when we look at what happens when batteries are charged and discharged at different rates.We need to find a way to relate battery capacity to energy so that we can compare everything using the same measure. The simple equation:

Power

= Volts x Amps

indicates that if we multiply the Ah by volts we

will get Watt-hours which is energy, simply divide by 1000 to get from

Wh to kWh. For example a 48 Volt battery has a capacity of 200Ah, so

the energy stored is 48 * 200 = 9600Wh, divide by 1000 to get 9.6kWh.Engineers look to use measurement units which are appropriate to the task in hand, this is why we use kWh to measure energy and Ah for battery capacity. These are simply scaled and combined versions of the fundamental units used by physicists to describe the universe, it is just that they are more appropriate to our everyday tasks.

Before embarking on this task it is vital to quantify how much power (watts, or kW) is needed and how many kWh of energy must be stored. This quickly leads to a desire to reduce the power and energy demand. We have always looked for energy efficient appliances but this does not necessarily mean they are low power.

Why low power?

A standard kitchen kettle is 3kW and will boil a litre of water in about 2 minutes. Consider the consequence of using low energy kettle of 1kW; the same energy is transferred to boil one litre of water but it will now take three times longer, 6 minutes, which may be somewhat inconvenient. However, in our application there are some quite significant advantages in using the lower power kettle. If the PV system is producing 1200W then we can run the low-power kettle entirely on renewable energy, however the standard 3kW kettle will use 1200W from the PVs and the remaining 1800W from the grid or battery. During a sunny summer day the PV array will produce more than 3kW for a few hours at the middle of the day. It is a very different situation in the winter, it will never get to 3kW (2kW is about the maximum), however the PV array it could be producing over 1kW for 5 hours during a sunny winter day, and all that energy could be used locally.When using a battery and inverter there are additional advantages to operating at lower power. First it may be possible to use a lower power and therefore cheaper inverter. Secondly, the inverter is likely to operate more efficiently mid-way through its power rating rather than at the top of its power rating, but most importantly a lead acid battery will operate significantly more efficiently, we will look at charge/discharge efficiency and the peurket coefficient later.

Aside: It turns out I don't find the extra time needed to heat the low

energy kettle much of a bother. Since it now isn't worth waiting by the

kettle I tend to do something else like feed the chickens, refuel the

Aga or check emails while the kettle boils.

Energy Utilisation

Everyone will be different and indeed usage is different from day-to-day, but there are some things which can help best utilise the available energy. It will always be more efficient to use the generated electricity directly rather than charging the battery and then converting it back latter. Sequence appliances so they come on one after another means there will always be a steady load. Where possible put off the washing or baking until a day with sunshine or wind. There will always be a compromise between convenience and best utilisation.The Energy and Power Budget

Energy efficiency has always been a high priority so even our older appliances are fairly low energy. However, the latest developments in energy pricing have moved this aspect to a much more important consideration and it is certainly possible to purchase more efficient appliances today. To a great extent compulsory energy efficiency labelling is a godsend for those wanting to compare and it is a real incentive for manufactures to do better. Here are some of our electricity appliances: In all other respects this

is a modern kettle, concealed flat bottom

element, cordless base, except it has a 1kW element. It is marketed

towards caravan users, who often have power constraints and isn't too

expensive. As mentioned above there is no overall efficiency saving

because we need the same amount of energy to heat the water but reduced

power is useful.

In all other respects this

is a modern kettle, concealed flat bottom

element, cordless base, except it has a 1kW element. It is marketed

towards caravan users, who often have power constraints and isn't too

expensive. As mentioned above there is no overall efficiency saving

because we need the same amount of energy to heat the water but reduced

power is useful.It wasn't perfect however: I have had to repair the automatic switch and modify the internal cabling which was too short and went intermittent, also the water gauge is almost useless and is now scaled up.

We

previously had a gas powered tumble dryer, which although not

particularly efficient was much much better than electricity. When we

moved to a non-mains gas area I enquired about a propane conversion,

but was told by the manufacturer it was "not possible". Hummm, odd how

I managed to rebuild the burner with an adjustable jet I made myself

and it worked fine for a few more years.

We

previously had a gas powered tumble dryer, which although not

particularly efficient was much much better than electricity. When we

moved to a non-mains gas area I enquired about a propane conversion,

but was told by the manufacturer it was "not possible". Hummm, odd how

I managed to rebuild the burner with an adjustable jet I made myself

and it worked fine for a few more years.When the time came to update, with all our solar production it seemed logical to go back to electric. However a conventional tumble dryer is both power and energy hungry, but there is an alternative ... heat pump tumble dryers use significantly less energy by 'dehumidifying' moisture out of clothes. The other major bonus is our AEG model has a power rating of only 800W (confirmed by measurement) compared to 3000W for a conventional electric dryer. It has a fairly long cycle time, but can sense the moisture level so automatically modifies the drying time to suit.

Problems with the dryer have been a lousy design of fluff filter with a polymer hinge which broke - TWICE. The chassis is not very stiff and if it isn't placed just right the fans rubs on the casing and the air path seal has failed due to distortion in the plastic so it leaks a bit of moist air. Overall I would have expected a lot better from a 'quality' German manufacturer.

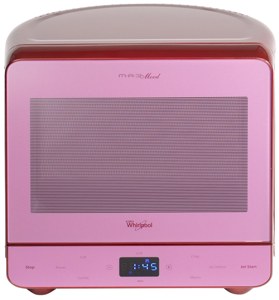

This

was purchased a year or so ago, a corner microwave: slides into a

corner with the electronics underneath the cooking plate rather than

along side. This makes for a compact unit but is still full size

cooking space.

This

was purchased a year or so ago, a corner microwave: slides into a

corner with the electronics underneath the cooking plate rather than

along side. This makes for a compact unit but is still full size

cooking space.I remember some of the older generation calling the microwave 'satan's oven', but as soon as you start looking at power and energy the microwave oven is far better than a conventional oven.

In keeping with a desire for lower power this is only rated at 700W so takes a little longer than some microwaves but not so much as to cause inconvenience. In addition it has an infra red grill. Overall very pleased and no faults or problems.

| Measured power consumption | |

| Microwave (full power) | 1350W |

| Grill | 700W |

| Combination both microwave and grill | 1700W |

| Idle (turntable light and fan) | 35W |

| Quiescent (clock) | 1.5W |

Start-up surge is controlled with the microwave ramping up to full power over a couple of seconds.

What

is to say about a toaster? It requires 800W per pair of slices and each

pair operate totally independently. Typical breakfast usage would be 4

slices of toast cooking and the kettle on, so that will be 2600W which

stays nicely within my notional 3kW maximum.

What

is to say about a toaster? It requires 800W per pair of slices and each

pair operate totally independently. Typical breakfast usage would be 4

slices of toast cooking and the kettle on, so that will be 2600W which

stays nicely within my notional 3kW maximum.We did try a 'eco' toaster which had an automatic cover over the slots to reduce heat loss, however it was hopeless at making toast! There is a lot more to making good toast that simply heating bread, the management of moisture is crucial, that is why toast under a grill (horizontal) is different from toast from an upright toaster. I suspect the slot covers on the 'eco' toaster trapped moisture leading to bad toast.

I want to save energy (and minimise power) but this can't be at the expense of getting the job done properly.

Dishwashers

are a common place time saving appliances, not that they entirely do

away with the need to wash up. We have had this Bosch for many years

and it has functioned faultlessly. We chose a 'low water consumption'

9-place setting machine because it seemed better to run the machine

slightly more often but full rather than risk running a bigger machine

half empty. In terms of energy consumption the 12-place setting

machines consumed at least a quarter more than the 9-place setting

machine so there was little advantage to the larger machine and a risk

it may be under-used.

Dishwashers

are a common place time saving appliances, not that they entirely do

away with the need to wash up. We have had this Bosch for many years

and it has functioned faultlessly. We chose a 'low water consumption'

9-place setting machine because it seemed better to run the machine

slightly more often but full rather than risk running a bigger machine

half empty. In terms of energy consumption the 12-place setting

machines consumed at least a quarter more than the 9-place setting

machine so there was little advantage to the larger machine and a risk

it may be under-used.I have measured our machine over many cycles and it consumes just under 1kWh to perform a standard 50°C 'eco' wash and dry. Newer models have a 40°C setting so I guess they will use less energy. It takes a tiny, but measurable, but more energy in winter, I suspect because the supply water is colder. The power supply for the control electronics is from a previous era when 'standby' consumption was of little consequence and it is noticeable. We therefore switch it off at the wall when not in use.

This

picture comes from the Bosch marketing literature and shows a freezer

almost identical to our earlier model, the specification and energy

consumption is identical and ours which also received the same "A"

rating.

This

picture comes from the Bosch marketing literature and shows a freezer

almost identical to our earlier model, the specification and energy

consumption is identical and ours which also received the same "A"

rating.What is worth noting is at the time "A" was the best energy rating possible, now it is middle of the pack! This is an excellent result and I believe in no small part by the introduction of compulsory energy labelling.

Previously it was only a geeky few who would trawl the specification sheets to find the true cost of ownership, now this is a standardised and obvious measure on the energy label. However, those of us wishing to pursue energy independence have other requirements such as power and start-up inrush current, so the energy label hasn't quite removed the need to delve into the technical specifications.

Fridges and freezer consume so much energy because they are on all the time and are one of the few appliances where it is worth replacing an older model before it wears out to save energy and money.

Refrigeration compressors are particularly hard loads to start and often cause the mains supply to dip as they switch on due to the very large inrush current. This will be a further consideration when later we look at inverters but I am pleased to our this freezer must have a soft start circuit because it is relatively easily load to drive.

The important measure is annual consumption at 223 kWh, actually ours does better than this because it is in a cool out-building, nevertheless 0.6kWh per day is significant and there is not option to only use it when the sun shines or wind blows.

A+ rated Siemens fridge/freezer

Electric fan oven (element changed for 2500W)

A++ Hoover washing machine

Grundfoss inverter driven central heating pump

Lighting: all LED or compact fluorescent

Household quiescent including: Wireless router (active) + range extender + LAN-to-wireless adaptor, telephone base station and handsets, HDD TV recorder, DVD HDD recorder, TV(standby), low voltage lighting transformers, PIR sensor lights, Solar PV inverter (asleep, but logging data) = 70W

Battery

From the energy budget and the desire to be off-grid autonomous for a few days as if a battery greater than 25kWh capacity will be needed. With my experience using lithium batteries on various electric car projects and the fact I had already developed a battery management system I was keen to use lithium. The characteristics of lithium batteries really do leave other technologies behind: excellent charge/discharge efficiency, low self-discharge loss, high power delivery and ability to safely discharge to a low state-of-charge without causing damage make them an extremely attractive option. The only down side is the price … at circa £20000 to build a suitably sized battery it is just too much for this project. Maybe when EV batteries start to come onto the second-hand market it would be worth looking again.So for the time being it was the hundred year old lead-acid technology which would be the only viable 'big battery' solution. Modern lead-acid batteries are highly optimised and the huge weight of lead is not a problem in a stationary battery application.

| Pros | Cons |

|

|

A lead-acid system will need around 20% more energy input to cover the additional losses compared to a lithium system, but it would be significantly cheaper to install more renewable power generation rather than pay for a superior battery.

Only thick plate, deep discharge storage or traction batteries are being considered. An automotive battery would be a very poor choice and have a short lifetime. Larger batteries are made up of individual 2V cells connected in a string to create the necessary overall battery voltage. A higher voltage delivers more power at lower current so can uses thinner connecting wires however it require more cells to be connected together and voltages above 60V are hazardous. Usually, batteries of this energy level are either 24V (12 cells) or 48V (24 cells).

Battery selection is a matter of evaluating cost per Ah, with a factor to cover other features and life expectancy. There are many to consider … gel electrolyte offer the best in maintenance free operation, but flooded tubular plate are cheaper and tougher especially under deep discharge conditions.

Cells specifically manufactured for solar storage called OPzS are available from a number of manufactures, these have solid cases with extra electrolyte volume to increase the time between watering. An alternative OPzV series are similar and used for traction applications like fork lift trucks, they have soft cases and are meant to be assembled into a steel battery tank. Following discussion with a supplier it appears the internal cell construction is identical so I elected to go with the lower cost OPzV and accept the need to replenish water more often.

Sizing the battery is a matter of optimising a number of contradictory conditions.

Too big a battery will waste more energy in self-discharge and by spending more time in the low efficiency absorption charging phase. The battery will expire due to chronological ageing rather than cyclic use.

Too small a battery and it will have a hard time delivering the peak power, discharging at high rates significantly reduces the available capacity (see perkurt coefficient) aggravating the situation further. The battery will as a consequence spend more time in a low state-of-charge which reduces life.

Consideration of battery capacity

A sensible starting point would be to look at the power budget and identify what load will be commonly applied, not the quiescent but when doing things. Since my target was to aim at circa 1kW (eg kettle or microwave or tumble-drier) this leads to a minimum capacity of 20kWh so that the discharge current is less than the C20 rate. Now looking at the normal maxima of 3kW, which would be the electric oven or washing machine during water heating; to achieve a C20 discharge rate would need a 60kWh battery pack. Assuming, as seems likely, that we will use a 48V battery this would require 24 cells each with a capacity of between 420Ah and 1260Ah.Now consider autonomy, the time we wish to support the system without any input power. While there is a desire to be grid independent, this is not absolutely essential. Looking back at the solar record this should be easily achievable April to September, with sufficient for hot water too. There is no time where over 5 days the battery becomes discharged below 50%. There may be a deficit in hot water but that could be sorted with a large buffer tank. In December and January the PVs only produce a third of the requirement, but when the wind turbine comes back on-line that deficit should easily be filled. A 5 day autonomy seems to be a logical target. Average winter usage is 8kWh per day with another 1kWh allowance to operate the inverter and associated control/monitoring equipment, this leads to a target of 45kWh backup capacity. A battery should not be discharged below 20% state-of-charge, but there is never a situation where there is zero energy input so 45kWh would actually last longer than 5 days without going below 20% SoC.

Cell Selection

These cells are rated at 840Ah at C5 discharge rate and 1050Ah at C20 discharge rate. and have a lifetime of 1500 cycles to 80% depth-of-discharge. Limiting the discharge to 50% would extend the life to 2500 cycles. Life can be further enhanced by reducing the concentration of sulphuric acid, although this reduces the capacity of the battery too.Inverter

The power budget suggests a minimum of 5kW, while manageable this would restrict usage to a single major heating appliance at any time. Eight kW would be a much better size allowing more-or-less any usage scenario without worry. An alternative arrangement would be to use a grid connected inverter to supply all the power needed up to its rating and then allow some to be imported from the grid to top up – this is a good configuration for a lower power inverterA separate inverter and battery charger was considered. The idea being to link them with a micro-controller to adjust the charge rate to balance any excess energy so none was exported to the grid.

After some discussion and a visit to Energy Solutions I was convinced the easiest solution was to use their Quattro Inverter and Charger. option was and a kind offer of a slightly second hand Victron Energy 10kW Inverter & 140A Charger -- how could I refuse?

The Quattro is an inverter and battery charger and transfer switch built into a single package. Victron Energy have been producing this type of kit for the marine market for many years, with self sufficiency off-grid applications. With the advent of feed-in-tarrif government supported home energy generation the 'self use' this technology has found a new market.

In the next part I will build a battery and install the inverter ...